Hardmetal Engineering

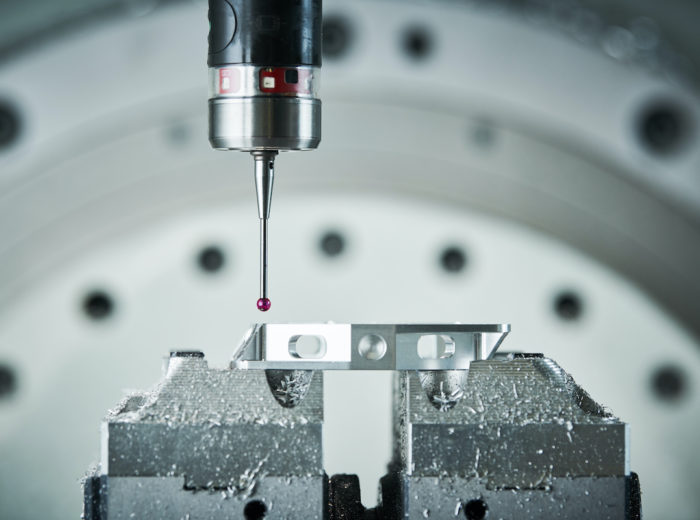

Our Hardmetal Engineering division specialises in the machining of complex components from very hard metals to incredible tolerances.

Imagine a human hair. Now imagine something 20 times finer. That’s four microns… and the tolerance routinely achieved by Hardmetal in fashioning some of the hardest metals on the planet.

Founded in 1979, we have an unquestionable level of experience and our Hardmetal Engineering division is one of the leading engineering companies in Europe working specifically with hard metals. We specialise in producing a wide range of wear products, piece parts and punch die sets in a variety of different materials for a broad spectrum of industries. We are experts in close tolerance working (normally within 4 microns) on Kovar, Tantalum, Titanium, Tool Steel, Brass, Copper Tungsten, Tungsten Carbide and sintered materials.

Working with some of the hardest metals in the world and the complex challenges surrounding it, demands an additional level of knowledge that is simply not available in the vast majority of the precision engineering sector.

In order to maintain and increase the stringent levels of accuracy that we regularly achieve, our Hardmetal department has specialist tooling and machinery, along with knowledge of specialist coolants and lubricants, designed to work specifically with hard and exotic metals.

The company retains its place at the forefront of the industry – and ahead of its competitors – through constant investment in state-of-the-art machinery and in on-going training of both skilled personnel and apprentices.

Our machinery, tooling and equipment is dedicated to working with some of the hardest materials on the planet, and our extensive expertise in this area is second to none.

Our core capabilities lie within the outstanding technical support we offer our customers, as well as the quality manufacture of a first-class product achieved through the exceptional skill and experience of our award-winning workforce.

Our Capabilities

Unique parts for the most demanding situations, from prototypes to full production runs. Our highly experienced designers will support your machining project from start to finish.

Machines

Industry wide we are recognised for our precision CNC machining, advanced infrastructure and engineering excellence

Find out moreMaterials

From Tungsten Carbide to Inconel to Aluminium and everything in between, we work with a wide range of metals

Find out more